Croissants are a beloved pastry and a staple in many bakeries and households around the world. While they may seem simple, creating the perfect croissant requires meticulous attention to detail, including the shaping process. There are two main techniques for shaping croissants: pre-shaping and final shaping. In this article, we’ll cover everything you need to know about these two techniques and how they can impact the overall quality of your croissants.

Understanding the difference between pre-shaping and final shaping.

Pre-shaping and final shaping are two distinct methods used to shape croissants during the pastry-making process. As the name suggests, pre-shaping involves shaping the dough before the final shaping is done. Final shaping, as the name suggests, is the final step where the dough is shaped right before baking. When dough is pre-shaped, it is typically done in a manner that is less detailed, but still manages to create a rough shape that will be further refined in the final shaping.

The importance of proper shaping in croissant making.

Without proper shaping techniques, croissants may not achieve the desired texture or appearance. Proper shaping ensures that the dough is evenly distributed, resulting in an even bake and consistent flakiness throughout the pastry.

In addition to ensuring even distribution of dough, proper shaping also plays a crucial role in the final presentation of the croissant. A well-shaped croissant will have a distinct crescent shape with defined layers, while a poorly shaped one may appear misshapen or flat. Additionally, proper shaping can also affect the overall size of the croissant, as a tightly rolled croissant will be smaller than one that is loosely rolled.

The benefits of pre-shaping in the croissant-making process.

Pre-shaping can make the final shaping process smoother, as a base shape is already established. This helps in achieving a consistent appearance for all croissants, and also saves on time. Pre-shaping can also be easier for beginners, as it gives them a chance to practice shaping without pressure. Additionally, pre-shaping gives the croissant an initial structural integrity that is important for its final, desired flakiness.

Another benefit of pre-shaping is that it allows for better control over the amount of filling that is added to the croissant. By pre-shaping the dough, you can create a well in the center where the filling can be placed, without it spilling out during the final shaping process. This ensures that each croissant has the same amount of filling, and also prevents any leakage during baking.

Pre-shaping can also help to develop the gluten in the dough, which is important for creating the desired texture of the croissant. By folding and shaping the dough during the pre-shaping process, you are stretching and strengthening the gluten strands, which will result in a more elastic and airy croissant. This is especially important for croissants that are filled with heavier ingredients, such as chocolate or almond paste, as the gluten structure needs to be strong enough to support the weight of the filling.

How pre-shaping impacts the texture of croissants.

Pre-shaping is crucial in providing structure to the pastry. This structure helps the pastry hold its shape when baked, and provides flakiness in the final product. Without pre-shaping, the dough may not have the desired structure, resulting in a less flaky texture.

Additionally, pre-shaping allows for the dough to rest and relax, which is important in achieving the desired texture. During the pre-shaping process, the dough is rolled and folded multiple times, which helps to evenly distribute the butter and create layers. This creates the signature flaky texture that croissants are known for.

However, it is important not to overdo the pre-shaping process, as this can lead to a tough and dense pastry. It is a delicate balance between providing structure and allowing the dough to rest and rise properly. Experienced bakers know the perfect amount of pre-shaping needed for their specific recipe and adjust accordingly.

The science behind final shaping and its effect on croissant quality.

Final shaping is where the desired shape and texture of the croissant is achieved. The dough is rolled out into a thin sheet and then shaped into the signature crescent shape, or a different shape depending on preference. Final shaping enables the dough to have the desired layers and texture, resulting in the characteristic flaky, buttery croissant.

However, final shaping is not just about aesthetics. It also plays a crucial role in the croissant’s overall quality. The way the dough is shaped affects the distribution of butter and air pockets within the layers. If the dough is not shaped properly, the croissant may end up with uneven layers or a dense texture. On the other hand, a well-shaped croissant will have a light, airy texture and a perfect balance of buttery flavor throughout.

Tips for achieving the perfect shape for your croissants.

To achieve the perfect shape for your croissants, it is essential to practice consistency and patience. Ensure the dough has rested adequately and is rolled out evenly. Use a consistent amount of dough when shaping to ensure the pastries are uniform in size. Ensure that the corners of the dough are stretched and that the folds are even.

Another important tip for achieving the perfect shape for your croissants is to use a sharp knife or pastry cutter when cutting the dough. This will ensure clean and precise cuts, which will help the croissants to rise evenly and maintain their shape during baking. Additionally, make sure to brush the croissants with egg wash before baking to give them a beautiful golden brown color and a shiny finish.

Key factors to consider when deciding between pre-shaping and final shaping.

When deciding between pre-shaping and final shaping, it is crucial to consider the amount of time, expertise, and resources you have available. Pre-shaping can save time and is simpler, but it may not provide the same level of detail and finesse that final shaping can. Final shaping, on the other hand, requires more time and skill, but the end result may be more visually appealing.

Another important factor to consider is the type of dough you are working with. Some doughs, such as those with high hydration levels, may require pre-shaping to help them hold their shape during final shaping. Other doughs, such as those with lower hydration levels, may be easier to work with during final shaping without the need for pre-shaping. It is important to experiment and find the method that works best for the specific dough you are working with.

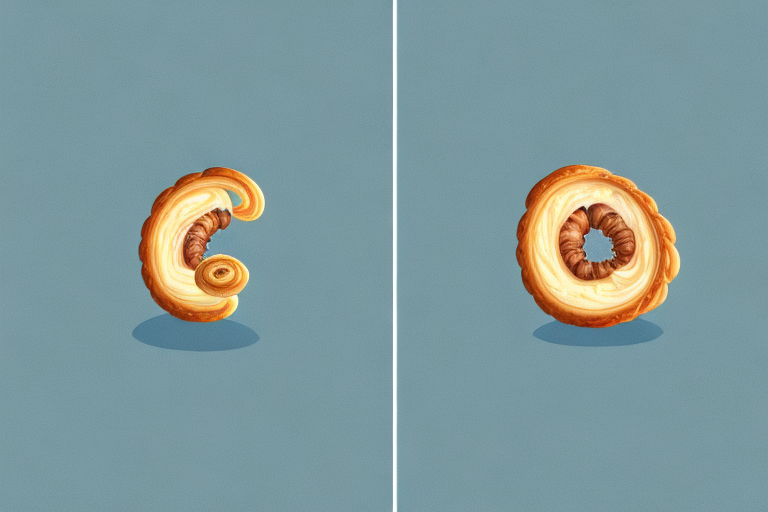

Real-life examples: A comparison of pre-shaped vs. finally shaped croissants.

In a real-life experiment, pre-shaped croissants were found to be less uniform in appearance than finally shaped ones. The pre-shaped croissants also lacked the desired flaky texture. However, pre-shaped croissants may be sufficient for some cases, such as mass-produced croissants where uniformity is a priority over aesthetics.

Another factor to consider when comparing pre-shaped and finally shaped croissants is the time and labor required for each method. Pre-shaped croissants can save time and labor in the production process, as they are already partially shaped and require less handling. Finally shaped croissants, on the other hand, require more time and skill to shape properly, but can result in a higher quality product with a more artisanal appearance.

It is also worth noting that pre-shaped croissants may have a longer shelf life than finally shaped ones, as they are often frozen and then baked as needed. Finally shaped croissants, on the other hand, are typically baked fresh and have a shorter shelf life. This may be a consideration for bakeries or cafes that need to balance the desire for a high-quality product with the need for efficiency and cost-effectiveness.

Expert advice on achieving consistent results with both pre-shaping and final shaping techniques.

To achieve consistent results with both pre-shaping and final shaping techniques, it is crucial to follow a properly documented and tested recipe that suits your specific needs. Additionally, practice makes perfect, so consistently making and shaping dough can help you refine your skills and achieve the desired results.

Another important factor to consider when working with pre-shaping and final shaping techniques is the temperature of your dough. The ideal temperature for dough during shaping is between 75-80°F. If the dough is too cold, it will be difficult to shape and may tear or break. If the dough is too warm, it will be sticky and difficult to handle. Therefore, it is important to monitor the temperature of your dough throughout the shaping process to ensure consistent results.

How to troubleshoot common issues when shaping croissants.

Common issues when shaping croissants can include uneven layers, uneven shaping, or lack of flakiness. If the dough is too cold or too warm, this can affect its ability to hold its shape and result in a poor final product. Ensuring consistency in rolling and shaping will reduce the likelihood of these issues. Additionally, it is crucial to follow recipes and measurements accurately to ensure dough consistency.

Another common issue when shaping croissants is over-proofing. If the dough is left to rise for too long, it can become too soft and difficult to shape. To avoid this, it is important to monitor the dough closely during the proofing process and adjust the time accordingly. Another tip is to use a cooler environment for proofing, as this can slow down the rising process and prevent over-proofing.

Best practices for shaping croissants in a professional bakery setting.

In a professional bakery setting, time is of the essence, and it is crucial to ensure consistent results every time. Best practices for shaping croissants include organizing the workspace and ingredients, preheating ovens, and preparing dough in advance. Additionally, it is important to stay patient and focused, ensuring consistent rolling, shaping, and temperature throughout the process.

Another important aspect of shaping croissants in a professional bakery setting is to use high-quality ingredients. Using high-quality butter and flour can make a significant difference in the taste and texture of the final product. It is also important to use the correct measurements and ratios of ingredients to ensure the perfect balance of flavors and textures. Finally, it is essential to have a thorough understanding of the baking process, including the ideal temperature and humidity levels, to achieve the perfect croissant every time.

How to incorporate creative shapes into your croissant making process.

Croissants can be shaped in several ways outside of the classic crescent shape. Creative shapes can add excitement and visual appeal to the final product. Some popular croissant shapes include pinwheels, spirals, and hearts. To incorporate creative shapes into your croissant-making process, it is important to experiment with the dough in a way that is still feasible and works well with the overall recipe and final product.

Time-saving tips for efficient croissant shaping.

To save time when shaping croissants, several tips can be employed, including using pre-made dough, preparing the workspace in advance, and utilizing professional-grade tools such as pastry cutters. It is important to ensure that shortcuts are not being taken at the expense of the final quality of the pastry, however.

The role of shaping in achieving a perfect flaky texture for your croissants.

Shaping is a crucial step in achieving the perfect flaky texture for croissants. Proper shaping enables the dough to have an even distribution of layers, providing the desired flakiness. Consistency and patience in the shaping process can ensure a consistent, flaky, and delicious final product.

In conclusion, both pre-shaping and final shaping are crucial techniques in the croissant-making process. Proper dough shaping can make the difference between an average croissant and a truly exceptional one. Follow these tips and best practices to ensure consistent results and a delicious, flaky pastry!